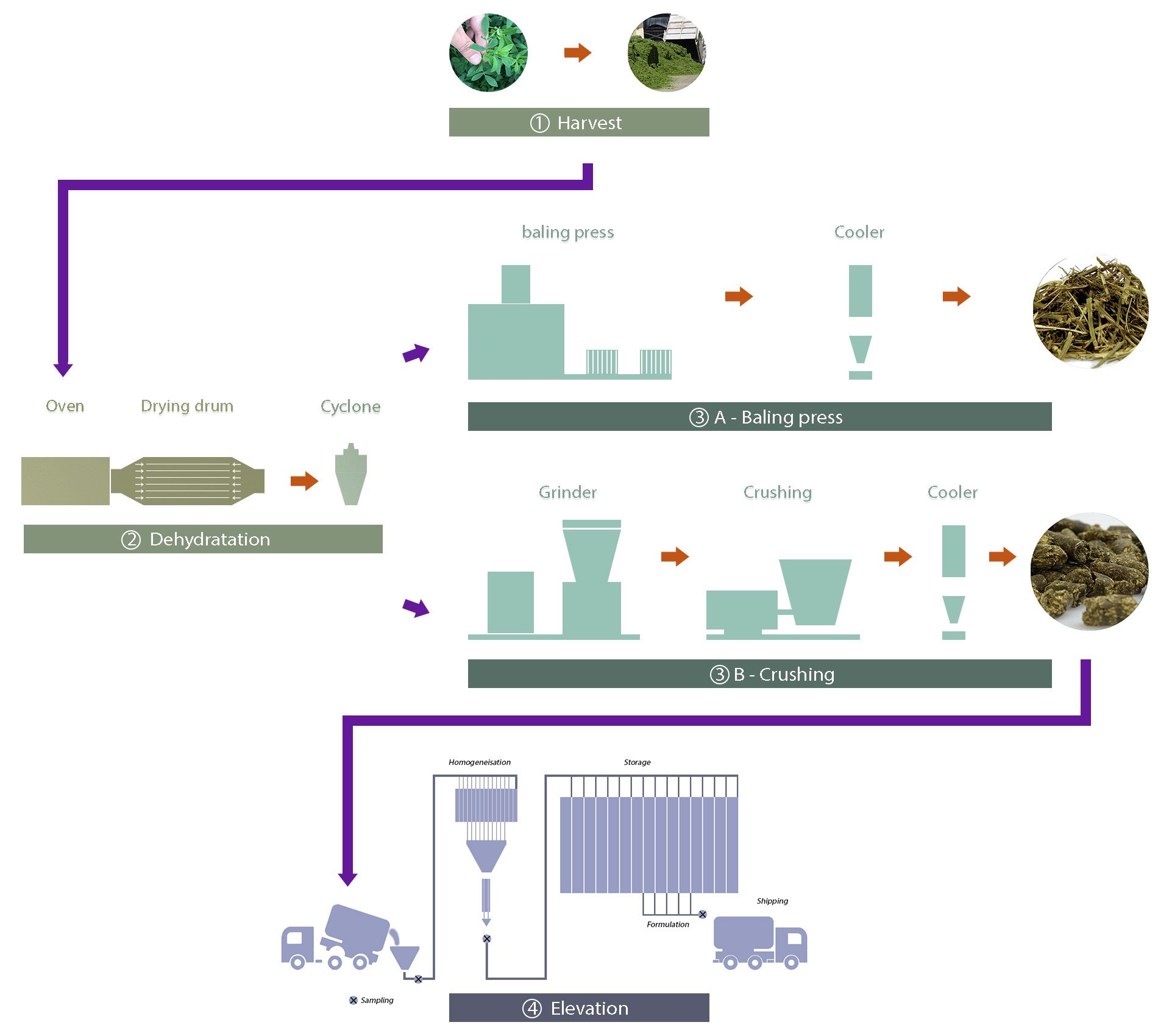

Dehydration process of alfalfa

A natural source of protein, alfalfa has been used as animal feed for more than 9000 years.

Dehydration, a unique drying process, is used for conservation and preservation of the fresh plant's nutritional qualities.

The constant improvement in dehydration, storage and homogenisation techniques has led to the diversification of qualities offered, expanding alfalfa consumption to all animal species.

The transformation of alfalfa is a natural, additive-free process.

1- Harvest

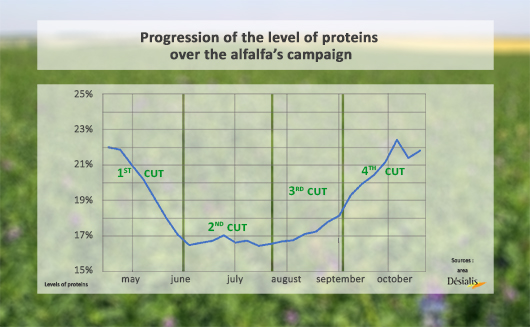

Respecting the harvest timetable is a fundamental part of quality.

It is drawn up to optimise transformation of the plant according to its vegetative stage. For better quality dehydrated products, we undertake to respect the cutting timetable for each raw material. To obtain the most suitable plant for manufacture of our various commercial qualities.

Example of alfalfa cutting timetable:

Alfalfa wilting

A process which consists of natural drying to lower the average humidity level of the alfalfa before dehydration, without altering its nutritional qualities.

2- Dehydration

Reduced by 75% to 50% moisture, the alfalfa wilted are transported to the dewatering, where they are dried in a rotary drum dryer.

With a current of hot air (between 250° and 600°C in dryer entrance), these are brought alfalfa to 10% moisture and then crushed.

3- Manufacture of commercial qualities

Dehydrated alfalfa in pellets

Crushing : On leaving the rotary drum dryer the alfalfa is crushed. The flour obtained is put into granulation presses to be agglomerated into pellets of different diameters 6 mm.

Fibre in bales: long-strand alfalfa in bales

At the exit of the drum dryer, the dried alfalfa uncrushed are oriented presses trunk to be packed in bales of 370 kg.

To produce RUMIPLUS, delicate (alfalfa leaves rich in protein), are retrieved, sorted, granulated (pellet of 6 mm) and reintroduced into bales of 420 kg.

4- Elevation

The dehydrated alfalfa is sent to our silos where it is homogenised, stored and formulated to obtain our commercial specialities.

Used to manage the variability of the qualities received (cuts and factory productions).

Homogenisation:

Consists of mixing the different qualities of alfalfa received to obtain homogeneous batches.

Storage:

The homogenised batches are checked, analysed and identified, then stored in dedicated cells.

Formulation:

Formulation, by mixing different homogenised batches (of identified, listed qualities), leads to the manufacture of our different commercial specialities, which will be guaranteed by contract.